Hard Seal Three Eccentric Flange Butterfly Valve

FEATURES

• Excellent sealing performance: The hard sealed three eccentric butterfly valve adopts a three-dimensional eccentric principle design, and the sealing ring is made of stainless steel, which has the dual advantages of metal hard seal and elastic seal. It has excellent sealing performance in both low and high temperature environments, and can maintain good sealing performance in high-pressure and high temperature environments, reducing the risk of leakage.

• Long life: Due to the unique design of the sealing pair, the valve has less friction during the opening and closing process, reducing the wear of the sealing surface and extending the service life of the valve.

• Wide applicability: Suitable for various fluid media, including gases, liquids, and even media containing particles. This characteristic has made it widely used in industries such as petroleum, chemical, and metallurgy.

• Quick switch: Compared to other types of valves, the three eccentric butterfly valve has a faster opening and closing speed, which can quickly cut off or open the fluid channel in emergency situations, improving the safety of the system.

• Small size and light weight: Compared to other types of valves of the same specifications, the three eccentric butterfly valve has a smaller volume and weight, making it easier to install and maintain.

• Strong corrosion resistance: The butterfly valve sealing ring is made of stainless steel, which has the characteristics of strong corrosion resistance and good elasticity, and can maintain good sealing performance in various corrosive media.

• Bidirectional sealing function: Metal hard sealed butterfly valves have bidirectional sealing function, which is not limited by the flow direction of the medium or the spatial position during installation, and can be installed in any direction.

• Diverse drive devices: The driving device can be installed at multiple stations (rotating 90 ° or 180 °), making it easy for users to use.

• Simple structure: The hard sealed butterfly valve has a simple structure, small volume, and light weight. It can be quickly opened and closed by rotating 90 °, with simple operation and good fluid control characteristics.

PARAMETER

• Design to comply with API609, JB/T8527, GOST P53673, Compatible with DIN, BS, JIS

• Connection standards HG/T20592, ASME B16.5, ASME B16.47, GOST 33259

• Face to face: ASME B16.10, GB/T12221, GOST 3706

• Testing & inspection: API598, GB/T13927, GOST 33257

• Body Material: WCB, CF8, CF8M, CF3M, 2205, 2507, 2520

• Disc Material: WCB, CF8, CF8M, CF3M, 2205, 2507, 2520

• Stem Material: 20Cr13, 17-4PH, 2205, 2507, 2520

• Seat Ring: Graphite+Metal(multilevel), PTFE+Metal, All-PTFE

• Transmission mode: Manual, Worm gear, Pneumatic, Electric, Hydraulic

• Applicable Temperature: -29~550 ℃

• Nominal diameter: DN50~DN2400, NPS 2”~NPS 96”

• Nominal pressure: PN6~PN100 / 150LB~600LB /10K~45K

PRODUCT STRUCTURE FEATURES

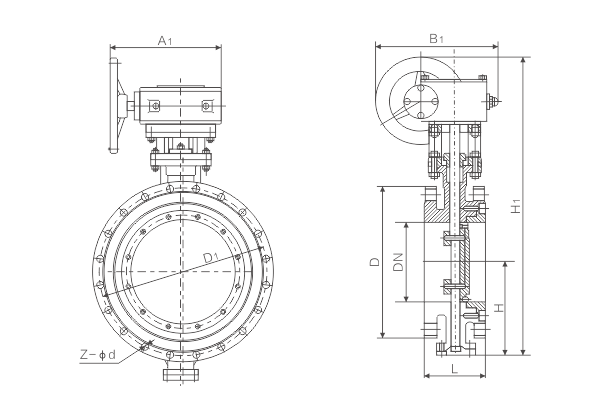

MAIN EXTERNAL CONNECTION DIMENSIONS

|

DN |

L |

H |

D343H |

D643H |

0943H |

PN1.6MPa |

PN2.5MPa |

||||||||||||

|

mm |

inch |

short |

long |

H1 |

A1 |

B1 |

H2 |

A2 |

B2 |

H3 |

A3 |

B3 |

D |

D1 |

Z-d |

D |

D1 |

Z-d |

|

|

50 |

2 |

108 |

150 |

112 |

350 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

165 |

125 |

4-18 |

165 |

125 |

4-18 |

|

65 |

21/2 |

112 |

170 |

115 |

370 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

185 |

145 |

8-18 |

185 |

145 |

8-18 |

|

80 |

3 |

114 |

180 |

120 |

380 |

180 |

200 |

645 |

245 |

72 |

565 |

250 |

255 |

200 |

160 |

8-18 |

200 |

160 |

8-18 |

|

100 |

4 |

127 |

190 |

138 |

420 |

180 |

200 |

675 |

355 |

92 |

600 |

250 |

255 |

220 |

180 |

8-18 |

235 |

190 |

8-22 |

|

125 |

5 |

140 |

200 |

164 |

460 |

180 |

200 |

715 |

355 |

92 |

640 |

250 |

255 |

250 |

210 |

8-18 |

270 |

220 |

8-26 |

|

150 |

6 |

140 |

210 |

175 |

555 |

270 |

280 |

800 |

355 |

92 |

705 |

300 |

315 |

285 |

240 |

8-22 |

300 |

250 |

8-26 |

|

200 |

8 |

152 |

230 |

200 |

760 |

400 |

425 |

850 |

250 |

170 |

775 |

300 |

315 |

340 |

295 |

12-22 |

360 |

310 |

12-26 |

|

250 |

10 |

165 |

250 |

243 |

830 |

400 |

425 |

925 |

250 |

170 |

945 |

300 |

315 |

405 |

355 |

12-26 |

425 |

370 |

12-30 |

|

300 |

12 |

178 |

270 |

250 |

895 |

450 |

560 |

1035 |

450 |

220 |

1070 |

300 |

315 |

460 |

410 |

12-26 |

485 |

430 |

16-30 |

|

350 |

14 |

190 |

290 |

280 |

950 |

450 |

560 |

1070 |

450 |

220 |

1140 |

300 |

315 |

520 |

470 |

16-26 |

555 |

490 |

16-33 |

|

400 |

16 |

216 |

310 |

305 |

1190 |

535 |

580 |

1190 |

450 |

220 |

1210 |

300 |

315 |

580 |

525 |

16-30 |

620 |

550 |

16-36 |

|

450 |

18 |

222 |

330 |

350 |

1255 |

535 |

580 |

1250 |

650 |

280 |

1335 |

575 |

714 |

640 |

585 |

20-30 |

670 |

600 |

20-36 |

|

500 |

20 |

229 |

350 |

380 |

1305 |

535 |

580 |

1290 |

650 |

280 |

1415 |

575 |

714 |

715 |

650 |

20-33 |

730 |

660 |

20-36 |

|

600 |

24 |

267 |

390 |

445 |

1340 |

570 |

660 |

1455 |

850 |

380 |

1605 |

656 |

810 |

840 |

770 |

20-36 |

845 |

770 |

20-39 |

|

700 |

28 |

292 |

430 |

480 |

1520 |

750 |

550 |

1585 |

850 |

380 |

1844 |

656 |

810 |

910 |

840 |

24-36 |

960 |

875 |

24-42 |

|

800 |

32 |

318 |

470 |

530 |

1710 |

750 |

550 |

1700 |

1250 |

380 |

2040 |

656 |

810 |

1025 |

950 |

24-39 |

1085 |

990 |

24-48 |

|

900 |

36 |

330 |

510 |

580 |

1810 |

750 |

550 |

1865 |

1250 |

380 |

2255 |

785 |

863 |

1125 |

1050 |

28-39 |

1185 |

1090 |

28-48 |

|

1000 |

40 |

410 |

550 |

650 |

1960 |

900 |

750 |

2015 |

1250 |

380 |

2380 |

785 |

863 |

1255 |

1170 |

28-42 |

1320 |

1210 |

28-56 |

|

1200 |

48 |

470 |

630 |

760 |

2250 |

1000 |

925 |

2250 |

1250 |

380 |

2640 |

785 |

863 |

1485 |

1390 |

32-48 |

1530 |

1420 |

32-56 |

|

1400 |

56 |

530 |

710 |

850 |

2435 |

1000 |

925 |

|

|

|

2886 |

|

|

1685 |

1590 |

36-48 |

1755 |

1640 |

36-62 |

|

1600 |

64 |

600 |

790 |

1030 |

2780 |

1000 |

980 |

|

|

|

3156 |

|

|

1930 |

1820 |

40-56 |

1975 |

1860 |

40-62 |

|

1800 |

72 |

670 |

870 |

1230 |

3020 |

1100 |

980 |

|

|

|

3421 |

|

|

2130 |

2020 |

44-56 |

2195 |

2070 |

44-70 |

APPLICATION

Water, sewage, seawater, air, steam, coal gas, combustible gases, corrosive media, oil products and food, etc.