Fluorine lined flange butterfly valve

FEATURES

• Small size and light weight: The fluorine lined flange butterfly valve has a small size and light weight, making it easy to install and maintain.

• Easy to operate: Easy to operate, suitable for frequent operations.

• Excellent sealing performance: Adopting a soft sealing structure, it has excellent sealing performance and can achieve zero leakage.

• Strong corrosion resistance: The valve body is lined with fluoroplastic material (Usually polytetrafluoroethylene), which can effectively resist the erosion of corrosive media such as acid, alkali, salt, etc.

• Long service life: Due to the use of high-quality lining materials and good sealing design, the service life is relatively long.

• Simple structure: The structure is simple, the switch is fast, and only 90 ° rotation is needed to open and close.

PARAMETER

• Design to comply with API609, ASME B16.34, HG/T3704, GOST P53673, Compatible with DIN, BS, JIS

• Face to face: ASME B16.10,GB/T12221, GOST 3706

• Testing & inspection: API598, GB/T13927, GOST 33257

• Connection type: Flange, Wafer

• Connection standards HG/T20592, ASME B16.5, ASME B16.47, GOST 33259

• Body Material: WCB+PTFE, CF8+PTFE

• Disc Material: QT+PTFE

• Transmission mode: Manual, Worm gear, Pneumatic, Electric

• Applicable Temperature: -29~150 ℃

• Nominal diameter: DN50~DN1000, NPS 2”~NPS 40”

• Nominal pressure: PN10~PN16 / 150LB /10K

PRODUCT STRUCTURE FEATURES

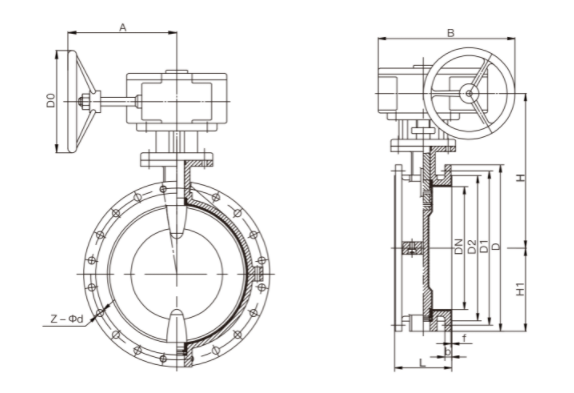

MAIN EXTERNAL CONNECTION DIMENSIONS

| DN | L | H1 | H | A | B | PN6 | PN10 | PN16 | |||||||||

| D | D1 | D2 | Z-Φd | D | D1 | D2 | Z-Φd | D | D1 | D2 | Z-Φd | ||||||

| 50 | 108 | 63 | 306 | 180 | 200 | 140 | 110 | 90 | 4-14 | 165 | 125 | 102 | 4-18 | 165 | 125 | 102 | 4-18 |

| 65 | 112 | 70 | 321 | 180 | 200 | 160 | 130 | 110 | 4-14 | 185 | 145 | 122 | 8-18 | 185 | 145 | 122 | 8-18 |

| 80 | 114 | 83 | 346 | 180 | 200 | 190 | 150 | 128 | 4-18 | 200 | 160 | 138 | 8-18 | 200 | 160 | 138 | 8-18 |

| 100 | 127 | 105 | 387 | 180 | 200 | 210 | 170 | 148 | 4-18 | 220 | 180 | 158 | 8-18 | 220 | 180 | 158 | 8-18 |

| 125 | 140 | 115 | 411 | 180 | 200 | 240 | 200 | 178 | 8-18 | 250 | 210 | 188 | 8-18 | 250 | 210 | 188 | 8-18 |

| 150 | 140 | 137 | 447 | 270 | 280 | 265 | 225 | 202 | 8-18 | 285 | 240 | 212 | 8-22 | 285 | 240 | 212 | 8-22 |

| 200 | 152 | 164 | 572 | 270 | 280 | 320 | 280 | 258 | 8-18 | 340 | 295 | 268 | 8-22 | 340 | 295 | 268 | 12-22 |

| 250 | 250 | 206 | 646 | 270 | 280 | 375 | 335 | 312 | 12-18 | 395 | 350 | 320 | 12-22 | 405 | 355 | 320 | 12-26 |

| 300 | 270 | 230 | 738 | 380 | 420 | 440 | 395 | 365 | 12-22 | 445 | 400 | 370 | 12-22 | 460 | 410 | 378 | 12-26 |

| 350 | 290 | 248 | 761 | 380 | 420 | 490 | 445 | 415 | 12-22 | 505 | 460 | 430 | 16-22 | 520 | 470 | 428 | 16-26 |

| 400 | 310 | 289 | 877 | 450 | 470 | 540 | 495 | 465 | 16-22 | 565 | 515 | 482 | 16-26 | 580 | 525 | 490 | 16-30 |

| 450 | 330 | 320 | 938 | 480 | 490 | 595 | 550 | 520 | 16-22 | 615 | 565 | 532 | 20-26 | 640 | 585 | 550 | 20-30 |

| 500 | 350 | 343 | 993 | 480 | 490 | 645 | 600 | 570 | 20-22 | 670 | 620 | 585 | 20-26 | 715 | 650 | 610 | 20-33 |

| 600 | 390 | 413 | 1131 | 480 | 490 | 755 | 705 | 670 | 20-26 | 780 | 725 | 685 | 20-30 | 840 | 770 | 725 | 20-36 |

| 700 | 430 | 478 | 1476 | 640 | 660 | 860 | 810 | 775 | 24-26 | 895 | 840 | 800 | 24-30 | 910 | 840 | 795 | 24-36 |

| 800 | 470 | 525 | 1533 | 640 | 660 | 975 | 920 | 880 | 24-30 | 1015 | 950 | 905 | 24-33 | 1025 | 950 | 900 | 24-39 |

| 900 | 510 | 585 | 1655 | 750 | 860 | 1075 | 1020 | 980 | 24-30 | 1115 | 1050 | 1005 | 28-33 | 1125 | 1050 | 1000 | 28-39 |

| 1000 | 550 | 640 | 1765 | 850 | 900 | 1175 | 1120 | 1080 | 28-30 | 1230 | 1160 | 1110 | 28-36 | 1255 | 1170 | 1115 | 28-42 |

APPLICATION

Sulfuric acid, hydrochloric acid, acetic acid, nitric acid, etc.