Hydraulic controlled slow closing check butterfly valve

FEATURES

• Can replace the pump outlet of the original electric gate valve and check valve function, electricity, liquid systems integrated into a whole, reducing land space and infrastructure investment.

• Electro-hydraulic control functions, without additional configuration that can be used as an independent system in stand-alone debugging and controlling; can also be used as a distributed control system (DCS) is a unit of equipment through the I/O channel by the central computer for centralized management, and realize linkage operation water pump and a water turbine, and bypass valve other pipeline equipment; and is equipped with manual function, no power supply can also be achieved manually open and close the valve, to meet the special conditions of the valve debugging and control requirements.

• Good controllability, wide range of adjustment and strong adaptability. The electro-hydraulic control system is provided with a plurality of transfer nodes, can according to different pipeline control requirements for opening and closing procedures, ensure to meet the opening and closing the valve condition, the valve can also can automatically according to the preset time, the opening angle and the fast and slow closing stage two. And can be closed without electricity, effectively eliminate the destructive water hammer, water pump and hydraulic turbine to prevent runaway accident, reduce the fluctuation of pressure pipeline system, ensuring the safe and reliable operation of equipment.

• The main valve sealing pairs of three eccentric metal or double eccentric rubber seal structure, open and close easy, sealed reliable, and there is an extra eccentric increase, so that the valve has a good self closing, self sealing performance. Medium and small diameter butterfly plate design plane double deck truss type structure, exclude small and smooth flow, the valve flow resistance coefficient is only 0.1~0.6, far less than the check valve flow resistance coefficient (1.7~2.6), the energy saving effect is obvious.

PARAMETER

• Design to comply with API609, ASME B16.34, JB/T5299, Compatible with DIN, BS, JIS

• Face to face: ASME B16.10, GB/T12221, GOST 3706

• Connection type: Flange

• Connection standards GB/T9113, ASME B16.5, ASME B16.47, GOST 33259

• Testing & inspection: API598, GB/T13927, GOST 33257

• Body Material: WCB,QT450-1,80-55-06

• Disc Material: WCB,QT450-1,80-55-06

• Transmission mode: Hydraulic, Electric

• Applicable Temperature: -20~80 ℃

• Nominal diameter: DN300~DN3000, NPS 12”~NPS 120”

• Nominal pressure: PN2.5~PN16 / 150LB /10K

PRODUCT DESCRIPTION

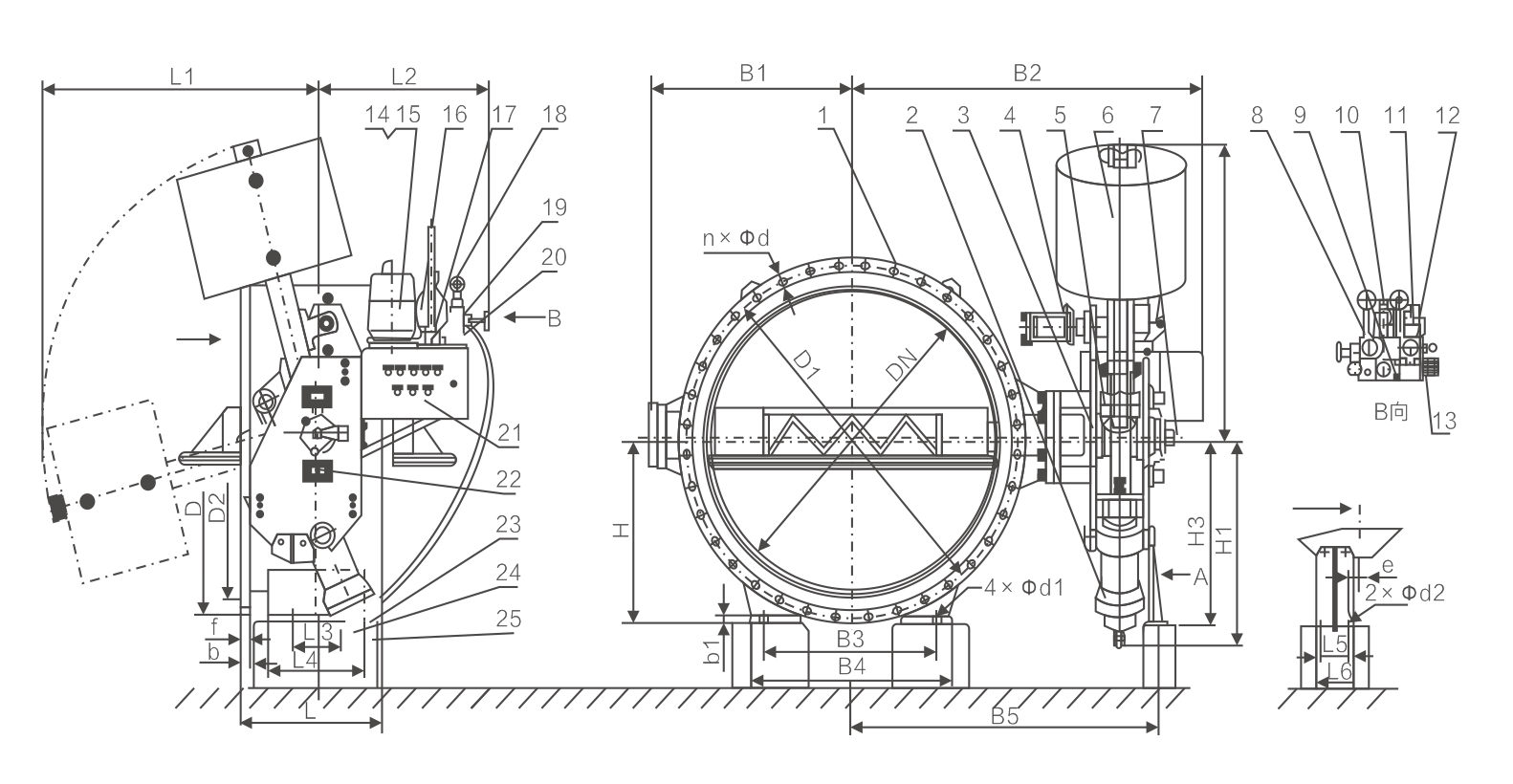

MAIN APPEARANCE AND CONNECTION DIMENSIONS(PN0.6MPA)

|

DN(mm) |

L |

D |

D1 |

D2 |

b |

f |

n |

d |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

H |

H1 |

H2 |

H3 |

|

1200 |

630 |

1405 |

1340 |

1295 |

28 |

5 |

32 |

34 |

1450 |

860 |

200 |

360 |

160 |

220 |

810 |

935 |

1350 |

685 |

|

1300 |

710 |

1520 |

1450 |

1405 |

32 |

5 |

32 |

37 |

1510 |

870 |

260 |

400 |

160 |

220 |

860 |

1065 |

1475 |

820 |

|

1400 |

710 |

1630 |

1560 |

1510 |

32 |

5 |

36 |

37 |

1765 |

870 |

260 |

400 |

160 |

220 |

940 |

1065 |

1475 |

820 |

|

1500 |

790 |

1730 |

1660 |

1610 |

34 |

5 |

36 |

37 |

1765 |

870 |

260 |

400 |

160 |

220 |

1000 |

1065 |

1475 |

820 |

|

1600 |

790 |

1830 |

1760 |

1710 |

34 |

5 |

40 |

37 |

1765 |

870 |

270 |

400 |

160 |

220 |

1080 |

1075 |

1720 |

820 |

|

1750 |

870 |

1995 |

1920 |

1868 |

36 |

5 |

44 |

40 |

1960 |

870 |

270 |

500 |

160 |

220 |

1130 |

1075 |

1720 |

820 |

|

1800 |

870 |

2045 |

1970 |

1918 |

36 |

5 |

44 |

40 |

1960 |

870 |

270 |

500 |

160 |

220 |

1130 |

1075 |

1720 |

820 |

|

2000 |

950 |

2265 |

2180 |

2125 |

38 |

5 |

48 |

43 |

2060 |

910 |

360 |

560 |

200 |

280 |

1250 |

1180 |

1990 |

910 |

|

2200 |

1000 |

2475 |

2390 |

2335 |

42 |

6 |

52 |

48 |

2060 |

910 |

360 |

600 |

200 |

280 |

1320 |

1180 |

1990 |

910 |

|

2400 |

1000 |

2685 |

2600 |

2545 |

44 |

6 |

56 |

48 |

2150 |

910 |

400 |

600 |

200 |

280 |

1440 |

1250 |

2080 |

980 |

|

2600 |

1000 |

2905 |

2810 |

2750 |

46 |

6 |

60 |

49 |

2150 |

910 |

500 |

700 |

200 |

280 |

1520 |

1250 |

2080 |

980 |

|

2800 |

1000 |

3115 |

3020 |

2960 |

48 |

6 |

64 |

49 |

2050 |

910 |

600 |

750 |

200 |

280 |

1620 |

1180 |

1990 |

1050 |

|

3000 |

1000 |

3315 |

3220 |

3160 |

50 |

6 |

68 |

49 |

2050 |

950 |

600 |

800 |

200 |

280 |

1720 |

1180 |

1990 |

1050 |

|

3200 |

1200 |

3525 |

3430 |

3370 |

54 |

6 |

72 |

49 |

2150 |

950 |

700 |

900 |

200 |

280 |

1820 |

1250 |

2080 |

1180 |

|

3400 |

1200 |

3735 |

3640 |

3580 |

56 |

6 |

76 |

49 |

2150 |

950 |

750 |

1000 |

200 |

280 |

1920 |

1250 |

2080 |

1180 |

|

3500 |

1200 |

3920 |

3780 |

3685 |

70 |

6 |

78 |

49 |

2150 |

950 |

750 |

1000 |

200 |

280 |

1980 |

1250 |

2080 |

1180 |

Application

Water, Seawater, Oil etc.